RM pressfit

MATHYS

RM pressfit

Monobloc cup

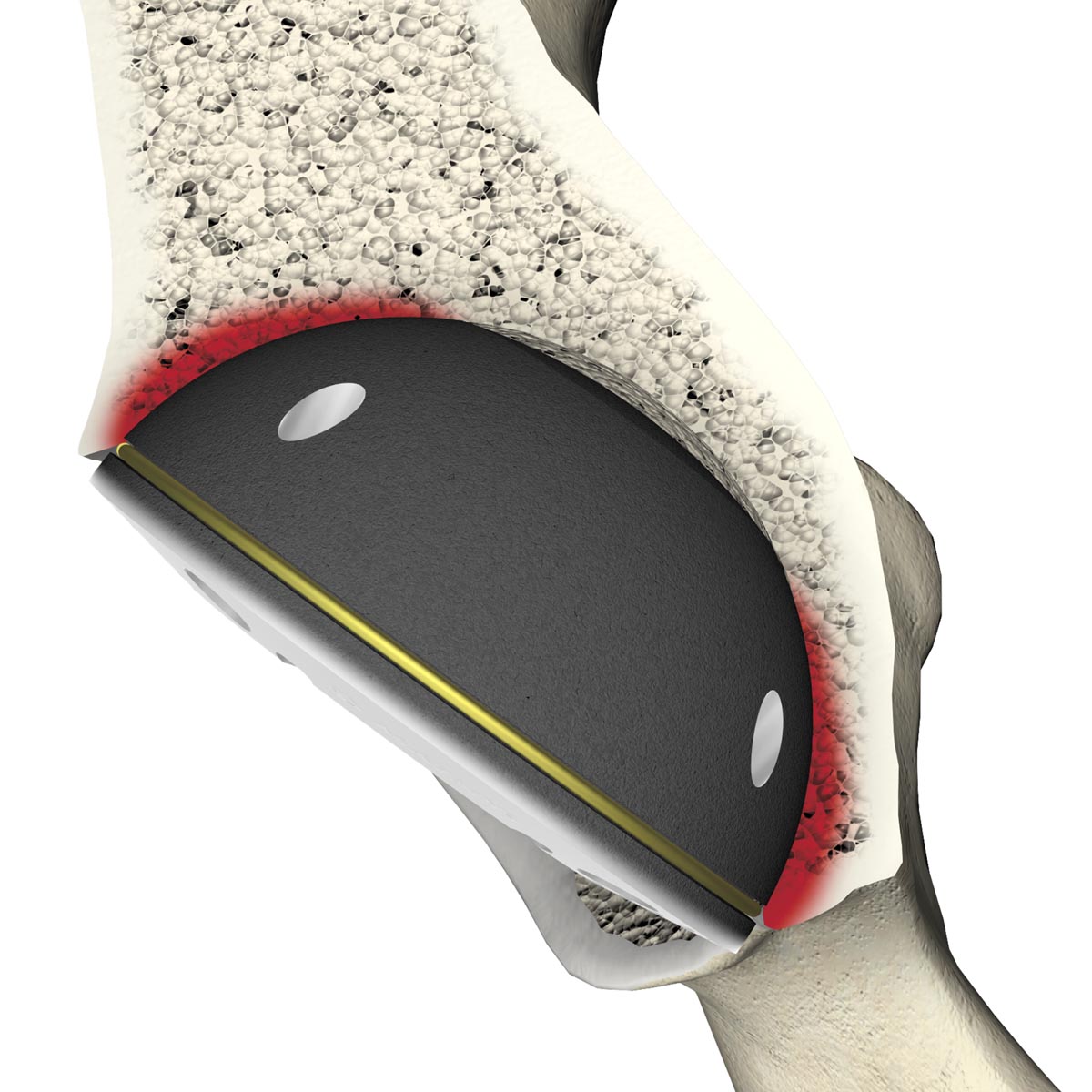

The RM Pressfit coated with titanium particles is an uncemented elastic monoblock cup made of UHMWPE, representing the advancement of the proven RM Classic Cup system1. With a mean survival rate of 94.4% for aseptic loosening after 20 years2, the RM Classic is one of the most successful uncemented acetabular cups worldwide.

The RM Pressfit cup achieves its primary stability through an equatorial press-fit. Aided by the flattening of the polar region, compressive forces are guided towards the periphery of the acetabular cup.3

The coating comprises a thin layer of non-correlating, individually anchored titanium particles that have no structural stiffness between them.4 This and the elasticity of the UHMWPE material, which is very similar to human cancellous bone5, ensure that the load transfer and the biomechanical behaviour of the cup remain physiological after the implantation, with the aim of preventing stress shielding.6

A high polyethylene thickness of the cup, with a low contact stress, resulting in low wear.7, 8, 9

Enquire

For further information, questions regarding this product, or to discuss alternative solutions, please get in touch with your local Sales Specialist or our Head Office using the form or the contact details at the bottom of the page.

Stay in touch

NEWSLETTER

Sign up to receive email updates on new product announcements, insights on surgical techniques from surgeons, specialists, and sales representatives and industry trends, such as changes in regulations and new research findings.