DELTA Multihole TT

LimaCorporate

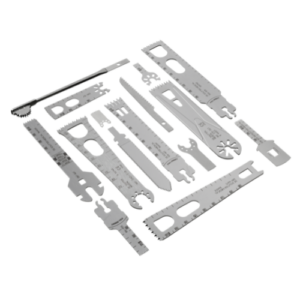

DELTA Multihole TT

DELTA Multihole TT System matches the innovative structure of TT Trabecular Titanium with the modularity of the DELTA acetabular cup system providing efficient solutions for revision treatment in case of bone deficiencies, both cavitary and segmental.

BENEFITS

- TT Trabecular Titanium ingrowths surface

- Intraoperative versatility & additional inferior screw fixation

- Lower rim to avoid femoral neck impingement and to allow for biomechanical adjustments with DELTA spacer technology

Enquire

For further information, questions regarding this product, or to discuss alternative solutions, please get in touch with your local Sales Specialist or our Head Office using the form or the contact details at the bottom of the page.

Stay in touch

NEWSLETTER

Sign up to receive email updates on new product announcements, insights on surgical techniques from surgeons, specialists, and sales representatives and industry trends, such as changes in regulations and new research findings.